Glossary of Softgel Terms

Softgels are one-piece capsules with a soft, gelatin-based shell enclosing a liquid or semi-solid fill, often used for supplements and medicines.

Key terms include the shell’s composition (gelatin, water, glycerin), the fill types (oil, solution, suspension), manufacturing processes like the rotary die encapsulation, and alternative types, such as vegan softgels made from plant-based materials like gellan gum and pectin.

Jump To A Section

Just Click on the first letter of the softgel term you want to lookup:

A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z |

A-B-C

Active Pharmaceutical Ingredient (API): The biologically active substance in a softgel responsible for the intended therapeutic or nutritional effect.

Altered Release: Prolong the release of the softgel active ingredients.

Bioavailability: The degree to which a softgel active ingredients can be absorbed into the bloodstream or intended site of action.

Bovine Gelatin: Gelatin derived from cow hides and bones used for softgel shells. Kosher or Halal certified bovine gelatins are available.

Caplet: A smooth, coated, and easy-to-swallow oral solid dosage tablet in the shape of a capsule but having the composition of a compressed tablet. Tablet in the shape of a capsule (elongated oval), often coated to mask taste.

Capsule: A dosage form in which the active ingredient is enclosed within a shell, usually made of gelatin or a plant-based substitute. Typically two pieces that fit together, containing dry powder or granules.

Carrageenan: A natural polysaccharide extracted from algae used as a plant-based alternative to animal gelatin in vegetarian softgels.

Chewable softgels: Designed to be chewed to release the liquid fill, often with a flavored shell.

Controlled-Release (CR) capsules: Designed to release medication slowly over an extended period.

Critical Process Parameters (CPPs): Key variables in the manufacturing process (e.g., drying temperature, gelatin mix viscosity, room humidity) that directly impact the Critical Quality Attributes of the softgels.

Critical Quality Attributes (CQAs): Measurable physical or chemical properties of the final product (e.g., fill weight uniformity, shell elasticity, disintegration time) that must be controlled to ensure quality.

Cross-linking: An undesirable chemical reaction, often caused by heat, humidity, or certain excipients, that forms extra bonds in the gelatin shell, potentially making it insoluble and affecting the drug release profile.

D-E-F

Die Rollers: Counter-rotating half-molds that form the capsule, seal the two halves together and trim the filled softgels during encapsulation.

Drying: Removing excess moisture from the softgels during manufacturing to achieve the required firmness and final moisture content. Initially done in rotary tumble dryers followed by further drying in heated static trays.

Encapsulation: The process of creating softgels, which uses a Rotary Die Encapsulation process to form, fill, and seal the capsules simultaneously.

Enteric Coating: A specialized softgel coating to prevent the capsule from dissolving in stomach acid allowing its contents to be absorbed in the intestines.

Excipient: Any non-active ingredient in the fill or shell material, such as oils, solvents, colorants, flavoring or preservatives.

Fill Material: The liquid, semi-solid, or suspension, which can be an oil or a solution, containing active ingredient(s) encapsulated inside the softgel shell.

G-H-I

Gelatin: A protein derived from collagen, traditionally used to make the capsule shell.

Gelcap: An unofficial, often marketing, term that is typically synonymous with “Softgel”. It can also refer to a hard capsule that has been sealed with a liquid band. Usually refers to a Softgel, implying a liquid-filled, elastic casing.

Gel Mass: The thick, molten, syrup-like mixture of gelatin, water, and plasticizer used to form the softgel ribbons that are then molded into softgel shells by the rotary dies.

Glycerin: A common polyol plasticizer used in the shell formulation to provide flexibility, elasticity, and prevent the shell from becoming brittle.

Good Manufacturing Practices (GMP): a system of regulations and guidelines ensuring products (especially food, drugs, cosmetics) are consistently manufactured to be high quality, safe, and suitable for their intended use. Topics covering everything from raw materials, quality assurance, regulatory compliance. facilities, equipment, staff training, documentation, etc. are included.

Gummy: A soft, chewable dosage form, resembling a confection, made primarily of gelatin, pectin, or starch and sweetened with sugars or sugar substitutes. Soft, chewy texture, various flavors and shapes, popular for vitamins and supplements.

Hermetically Sealed: A manufacturing term indicating that the capsule is airtight and seamlessly sealed, protecting the contents from oxygen, light, and moisture.

J-K-L-M

Lipophilic: A substance that is fat-soluble or mixes well with oils. Softgels are particularly suitable for encapsulating lipophilic active ingredients to improve their absorption.

Minim: A unit of volume used to measure the content of various sized softgels; one (1) “minim” is equal to one-sixtieth (1/60) of one fluid dram (approximately one drop of liquid). one (1) fluid dram = 1/8 U.S. fluid ounce = ~3.7 mL.

N-O-P-Q

NutriGenesis: A method of producing cultured nutrients where micronutrients are absorbed by a growth medium containing cultures, which then grow and generate vitamins and minerals within a matrix of cofactors that the body can recognize and absorb more easily.

Opacifier: An additive, such as titanium dioxide, used in the shell formulation to make the capsule opaque, typically to protect light-sensitive ingredients or mask the appearance of the fill material.

Plasticizer: A gelatin additive that makes the gelatin shell soft, flexible and resilient. Commonly used exmples include glycerin and sorbitol.

Porcine Gelatin: Gelatin derived from pig hides and bones used for softgel shells.

R-S-T-U-V

Rotary Die Encapsulation: The high speed manufacturing process in which two ribbons of shell material are brought together between rotating dies that form, fill, cut and seal the softgel capsules in one continuous operation.

Shell: The one-piece outer casing of the softgel, made from a combination of gelatin, water, a plasticizer (like glycerin or sorbitol), and an opacifier.

Softgel: A type of capsule characterized by a thicker, single-piece, elastic gelatin shell, typically used to contain liquid or oil-based active ingredients. One seamless piece, clear or opaque, often used for oils (like MCT) or liquid suspensions.

Suckable Softgels: A type of softgel intended to be sucked to release the fill contents.

Suspension: A type of fill material where solid active ingredient particles are dispersed uniformly throughout a liquid carrier (e.g., an oil or polyethylene glycol base).

Tablet: A solid dosage form containing one or more active ingredients and excipients (inactive substances), formed by compressing the powder mixture. Hard, often scored (line to break it), various shapes (round, oval, etc.).

Topical Softgels: A type of softgel designed for use on the skin.

Twist-off Softgels: A type of softgel with a tag that is twisted or snipped to access the fill contents.

Vegan Softgel: A softgel made with a plant-based shell materials like gellan gum, pectin, starch, carrageenan , etc., instead of animal-derived gelatin. Kosher or Halal certified gelatins are available.

Viscosity: A measure of a fluid’s resistance to flow. Both the gel mass and the fill material must have viscosities in a range that allows them to flow smoothly through the encapsulating equipment.

W-X-Y-Z

Wedge: The heated component in the encapsulation machine positioned between the two gelatin ribbons feeding into the rotary dies that injects the fill material and facilitates the thermal sealing of the capsule halves before they are cut by the die rollers.

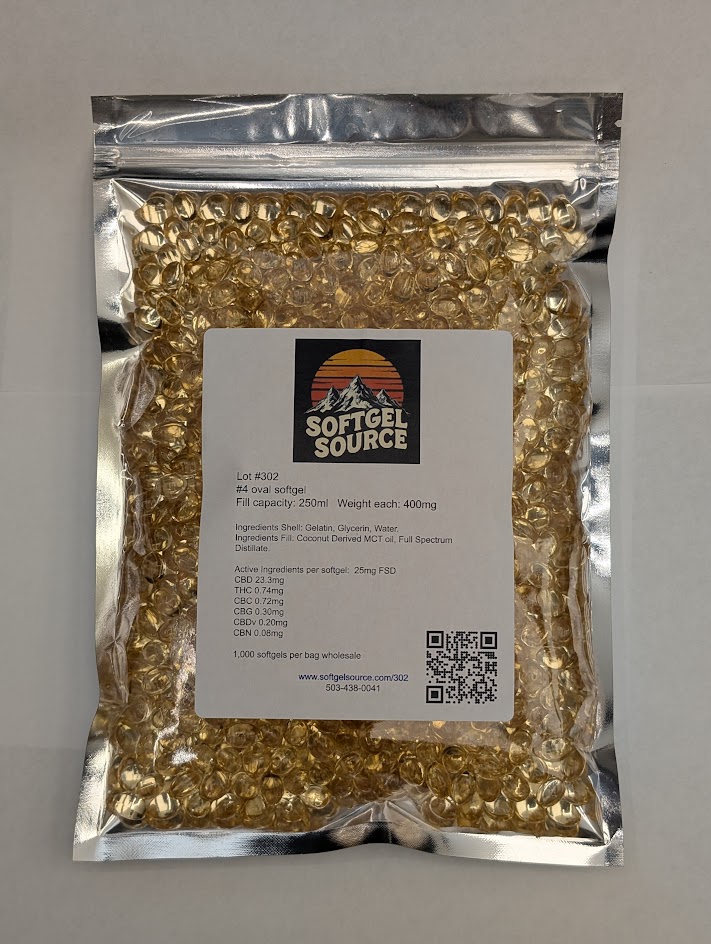

Softgel Source specializes in manufacturing custom softgel capsules for various ingredients including vitamins, medications, supplements and pet products. We handle the ingredient selection to insure compatibility with the softgel format, can source and formulate the fill material to specifications, test and validate to ensure efficacy, safety, and quality.

Contact us if you have questions about SoftGel Source, our products and our services

Copyright © 2024 – 2025, Softgel Source, LLC. All Rights Reserved.